Revolutionizing Jewelry Design and Production: The Power of 3D Scanning

Related Articles: Revolutionizing Jewelry Design and Production: The Power of 3D Scanning

Introduction

With great pleasure, we will explore the intriguing topic related to Revolutionizing Jewelry Design and Production: The Power of 3D Scanning. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Revolutionizing Jewelry Design and Production: The Power of 3D Scanning

The jewelry industry, renowned for its artistry and intricate craftsmanship, is undergoing a technological revolution. At the forefront of this transformation is the emergence of 3D scanning technology, a powerful tool that is reshaping the way jewelry is designed, manufactured, and experienced.

Understanding the Essence of 3D Scanning in Jewelry

3D scanning, in its simplest form, is a process that captures the physical dimensions and intricate details of an object, translating them into a digital representation. This digital model, a precise virtual replica of the original, can then be manipulated, analyzed, and utilized for various purposes. In the context of jewelry, 3D scanning offers a plethora of benefits, from streamlining design processes to enhancing production efficiency.

Key Applications of 3D Scanning in Jewelry

-

Design and Prototyping:

-

Rapid Prototyping: 3D scanning empowers jewelers to create prototypes quickly and efficiently. By scanning existing pieces or even sketches, they can instantly generate digital models that can be modified and iterated upon, accelerating the design process and minimizing material waste.

-

Reverse Engineering: This process involves scanning an existing piece of jewelry to obtain its precise dimensions and intricate details. This data can then be used to recreate the piece, allowing for accurate replication or adaptation for new designs.

-

Customization and Personalization: 3D scanning enables jewelers to cater to individual customer preferences by creating bespoke pieces. Customers can bring in their own jewelry or even personal items, which can be scanned and incorporated into unique designs.

-

-

Production and Manufacturing:

-

3D Printing: 3D scanning seamlessly integrates with 3D printing technology, allowing for the creation of complex jewelry designs with intricate details that would be challenging or impossible to achieve using traditional methods. This opens up new possibilities for design and customization.

-

Casting: 3D scanning data can be used to create precise molds for casting jewelry, eliminating the need for traditional wax carving and ensuring greater accuracy and detail.

-

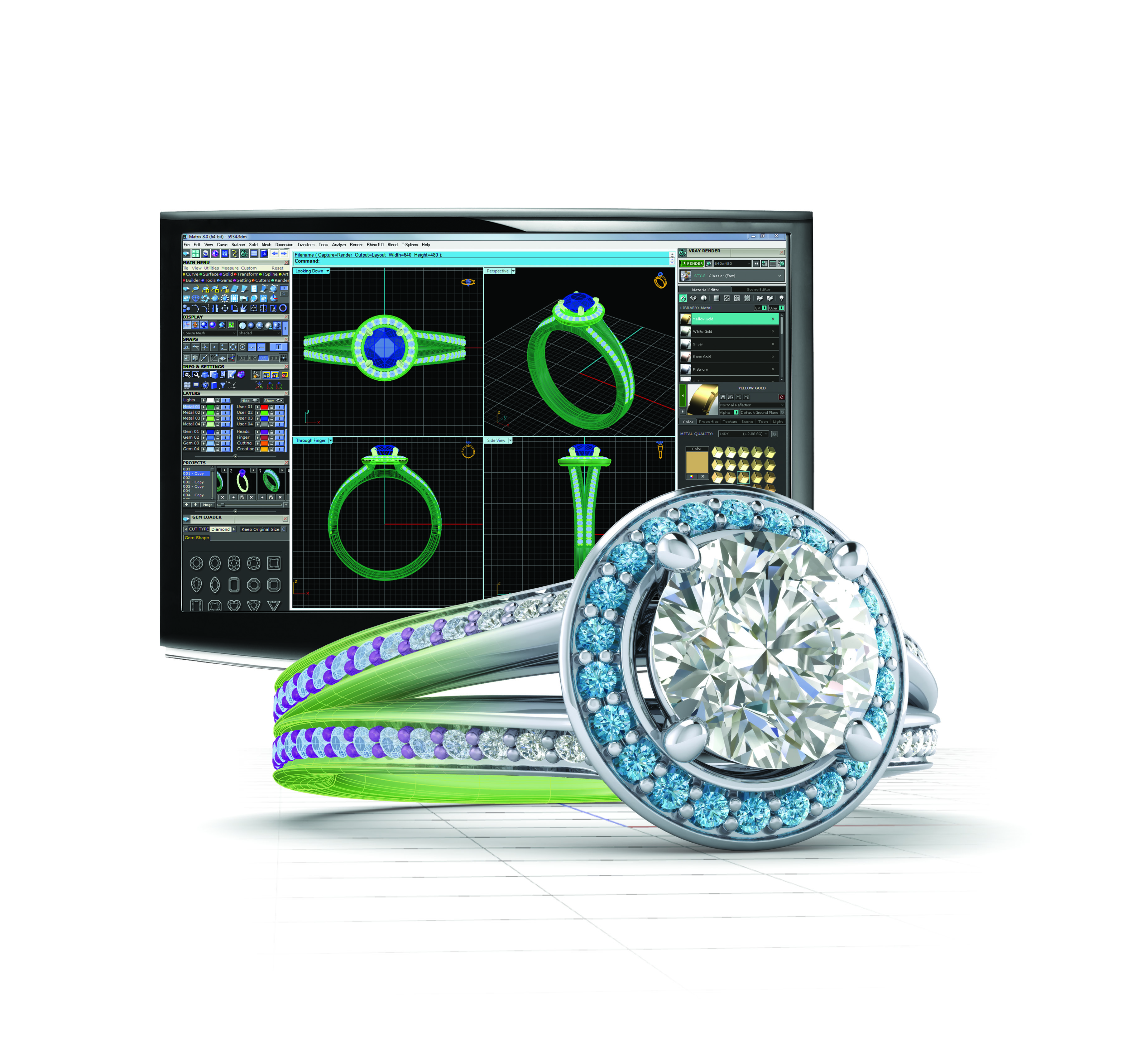

CAD/CAM Integration: 3D scanning data can be directly imported into CAD/CAM software, enabling jewelers to design and manufacture jewelry with increased precision and efficiency.

-

-

Quality Control and Inspection:

-

Dimensional Accuracy: 3D scanning provides a highly accurate and detailed representation of jewelry, allowing for meticulous quality control measures. Any deviations from the intended design can be identified and corrected before production, minimizing errors and ensuring consistent quality.

-

Inspection of Precious Stones: 3D scanning can be used to analyze the shape, size, and clarity of precious stones, ensuring their authenticity and quality.

-

Types of 3D Scanners Used in Jewelry

The jewelry industry utilizes a variety of 3D scanners, each with its unique advantages and limitations. The most common types include:

-

Structured Light Scanners: These scanners project a pattern of light onto the object, capturing its shape by analyzing the distortion of the projected pattern. They are known for their accuracy and speed, making them suitable for scanning intricate jewelry pieces.

-

Laser Scanners: Laser scanners use a laser beam to measure the distance between the scanner and the object, creating a point cloud that represents the object’s shape. They offer high precision and are particularly useful for scanning large and complex jewelry pieces.

-

Photogrammetry Scanners: This technique uses multiple photographs taken from different angles to create a 3D model. While it may require more processing time, it is a versatile method that can be used to scan objects of various sizes and shapes.

-

CT Scanners: Computed tomography (CT) scanners use X-rays to create detailed 3D models of objects, including their internal structures. This technology is particularly useful for analyzing the internal structure of precious stones or for creating 3D models of jewelry with complex internal designs.

Benefits of Using a 3D Scanner in Jewelry

The adoption of 3D scanning technology in the jewelry industry offers a multitude of benefits, revolutionizing design, production, and customer experience:

-

Enhanced Design Capabilities: 3D scanning empowers jewelers to experiment with complex designs, creating intricate and unique pieces that would be challenging or impossible to create using traditional methods.

-

Increased Efficiency and Productivity: By streamlining design and production processes, 3D scanning significantly reduces lead times and increases efficiency, allowing jewelers to produce more pieces in a shorter timeframe.

-

Reduced Costs and Waste: 3D scanning minimizes material waste by enabling precise prototyping and production. It also eliminates the need for traditional wax carving, further reducing costs.

-

Improved Accuracy and Quality: 3D scanning ensures precise dimensions and intricate details, resulting in higher-quality jewelry with consistent craftsmanship.

-

Personalized and Bespoke Jewelry: 3D scanning allows for the creation of customized and personalized jewelry, catering to individual customer preferences and creating unique pieces that reflect their individual style.

-

Enhanced Customer Experience: By offering personalized designs and quicker turnaround times, 3D scanning technology enhances the customer experience, fostering greater satisfaction and loyalty.

Factors to Consider When Choosing a 3D Scanner for Jewelry

Selecting the right 3D scanner for your jewelry business requires careful consideration of several factors:

-

Accuracy and Resolution: The accuracy and resolution of the scanner determine the level of detail captured in the 3D model. For intricate jewelry pieces, a high-resolution scanner is essential.

-

Scanning Speed: The scanning speed influences the efficiency of the process. Faster scanners are more suitable for high-volume production, while slower scanners may be sufficient for smaller-scale operations.

-

Scanning Area: The size of the scanning area determines the maximum size of the object that can be scanned. Choose a scanner with a scanning area that accommodates the size of your jewelry pieces.

-

Software Compatibility: Ensure that the scanner is compatible with your existing CAD/CAM software for seamless integration and data transfer.

-

Budget: 3D scanners come in a wide range of prices, depending on their features and capabilities. Set a realistic budget and consider the return on investment before making a purchase.

Frequently Asked Questions (FAQs) about 3D Scanners in Jewelry

Q: Are 3D scanners only for large jewelry businesses?

A: While 3D scanners can be beneficial for large-scale operations, they are also accessible to smaller businesses and even individual jewelers. There are affordable and user-friendly 3D scanners available that cater to different needs and budgets.

Q: What types of jewelry can be scanned?

A: 3D scanners can be used to scan a wide variety of jewelry, from delicate rings and earrings to intricate necklaces and bracelets. They can also be used to scan precious stones and other materials commonly used in jewelry making.

Q: How accurate are 3D scans?

A: The accuracy of 3D scans depends on the type of scanner used and the specific settings employed. However, modern 3D scanners are capable of achieving high levels of accuracy, capturing even the smallest details of jewelry pieces.

Q: What are the limitations of 3D scanning in jewelry?

A: While 3D scanning offers numerous advantages, it also has some limitations. For example, scanning highly reflective surfaces, such as polished metals, can be challenging. Additionally, capturing the exact texture and color of materials may require specialized techniques.

Q: What are the future trends in 3D scanning for jewelry?

A: The future of 3D scanning in jewelry is bright, with ongoing advancements in technology and applications. We can expect to see improvements in accuracy, speed, and affordability, making 3D scanning even more accessible and powerful for jewelers.

Tips for Using a 3D Scanner in Jewelry

-

Proper Preparation: Ensure the jewelry piece is clean and free of any debris or fingerprints. This will enhance the accuracy of the scan.

-

Appropriate Lighting: Use adequate lighting to ensure the scanner captures all the details of the jewelry piece. Avoid harsh shadows that can distort the scan.

-

Stable Positioning: Securely position the jewelry piece to minimize movement during the scan. This will ensure a consistent and accurate 3D model.

-

Software Calibration: Calibrate the scanner and software regularly to maintain accuracy and consistency.

-

Post-Processing: Use appropriate software to refine and optimize the 3D model, ensuring it is ready for use in design, production, or other applications.

Conclusion

3D scanning technology is transforming the jewelry industry, empowering jewelers to design, produce, and experience jewelry in new and innovative ways. From rapid prototyping and customization to enhanced quality control and production efficiency, 3D scanning offers a multitude of benefits, enabling jewelers to create exquisite and personalized pieces that delight customers and elevate the art of jewelry making. As 3D scanning technology continues to evolve, it will undoubtedly play an increasingly important role in shaping the future of the jewelry industry, driving innovation and pushing the boundaries of creativity.

Closure

Thus, we hope this article has provided valuable insights into Revolutionizing Jewelry Design and Production: The Power of 3D Scanning. We appreciate your attention to our article. See you in our next article!